Quality Assurance

- Home

- Quality Assurance

Inspection, Measurement and Testing

Certifications

ISO 9001: 2015

Our dedicated Quality Department are able to undertake a wide range of analysis, testing and measurement procedures. By carrying these out in-house, we ensure that all products are inspected from design to delivery – in a quick and efficient manner that doesn’t affect lead times.

Inspection Reports

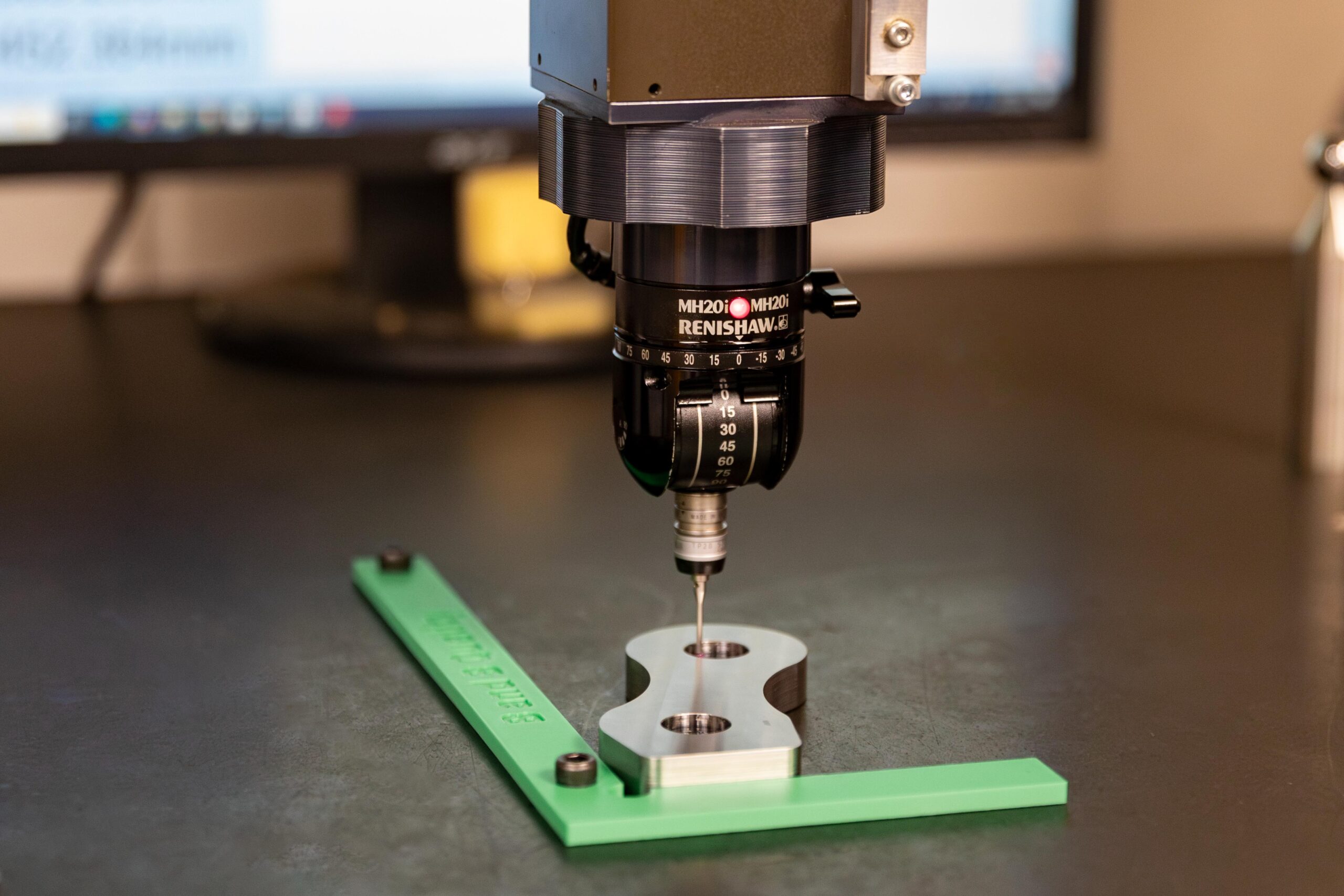

We can undertake a wide variety of bespoke inspection reports which includes: Hardness Testing, Surface Finish Measurements, Microscopic Structure Analysis, Adhesion Testing to ASTM C-633 and ASTM D4624. Our Quality Department includes a wide range of metallurgical inspection equipment as well as a CMM and Shadowgraph.

Metallurgical Laboratory

We have invested in the latest manufacturing technology and this is supported by a dedicated quality department that has a fully equipped in-house laboratory and extensive test and measurement equipment.

Quality Audits

As part of our dedication to continuous improvement, we undertake a full customer audit. We asked our customers to rate us on enquiries, production and quality and anonymously collected the data.

“I have been speaking to customers both large and small across a wide range of sectors, and even customers who have stopped using our services. It was very rare that someone cited Quality issues and often when they did, it was a small issue on one part to a client who we may process thousands of components,” said Oliver, who carried out the audit.

To support our commitment to accuracy, we’ve recently introduced a CNC-controlled CMM into our inspection workflow. Unlike manual machines, our CNC CMM offers fully automated, repeatable measurements – ideal for batch production and complex components. This investment allows us to deliver consistently high-quality results with improved speed and reliability.

Documents & Policies

Contact us

ISO Certificate

8512-ISO 9001:2015

DUNS Number

236438573

Company Registration No.

03639121

VAT Number

721236968