Surface Grinding

- Home

- Surface Grinding

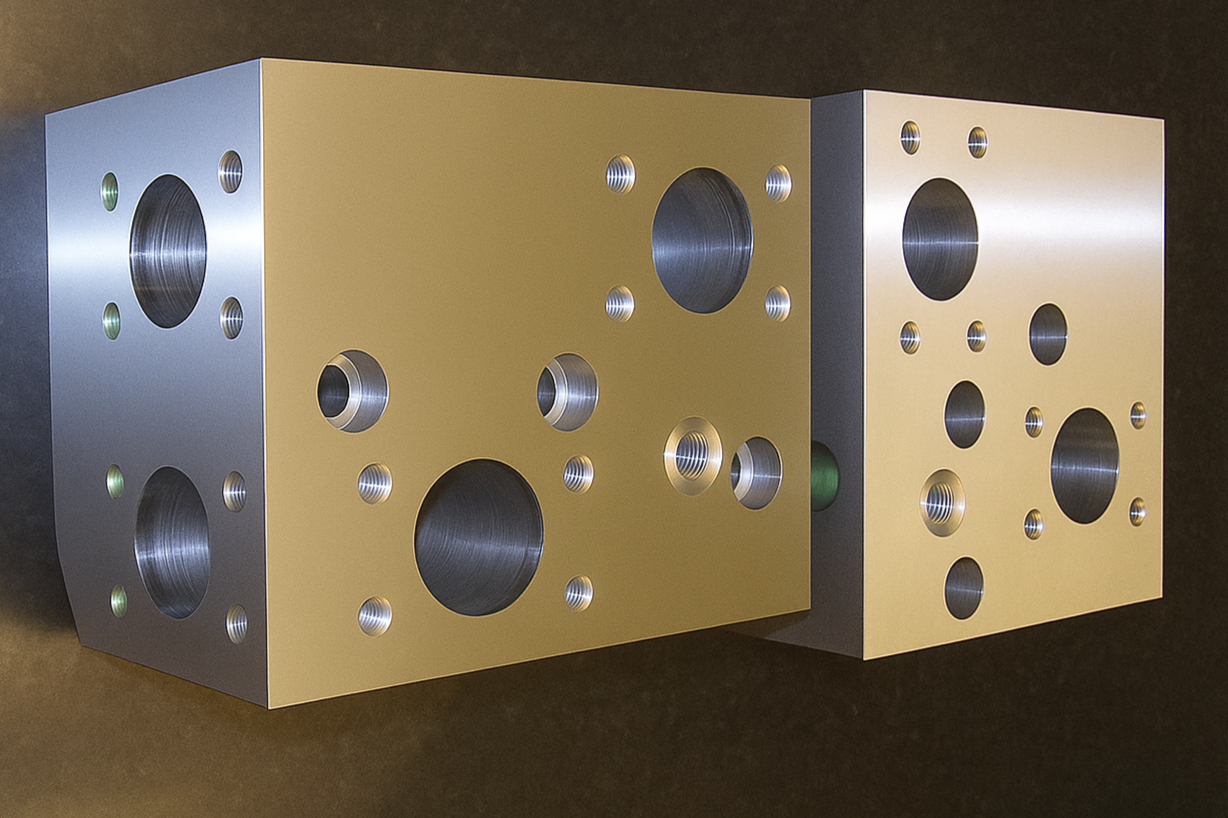

Surface Grinding 500mm x 2500mm

Grinding Capacity

Tschudin TL155U Universal Grinder: Max Diam 505mm x 1.5 metres long

Jones & Shipman Format 15 CNC Grinder: Max Diam 250mm x 70mm between centres

Jones & Shipman Uni Cylinder Grinder: Max Swing 300mm x 850mm between centres

Churchill Cylindrical Grinder: Max Diam 508mm x 2800mm between centres with DROA

Jones & Shipman 540 Surface Grinder: 450mm x 150mm magnetic table

Snow Hydraulic Horizontal Surface Grinder: Max Diam 310mm x 76mm Bar

Thompson Surface Grinder: 500 x 500 x 250mm magnetic chuck with demagnetiser

Contact us

ISO Certificate

8512-ISO 9001:2015

DUNS Number

236438573

Company Registration No.

03639121

VAT Number

721236968